Cov khoom tshwj xeeb ntawm ceramic brakes

Standard disc brakes muaj cam khwb cia hlau los yog steel discs thiab pads qhov twg cov muab tub lim yog ntxiv nrog hlau shavings. Thaum asbestos yog lub hauv paus ntawm kev sib txhuam hauv ob sab phlu, tsis muaj cov lus nug tshwj xeeb txog kev muaj pes tsawg leeg, tab sis tom qab ntawd nws tau pom tias asbestos fibers thiab plua plav tawm thaum lub sij hawm braking muaj zog carcinogenic zog. Kev siv cov asbestos raug txwv, thiab ntau yam organic tebchaw pib siv hauv cov ntaub qhwv. Lawv cov khoom tau dhau los ua tsis txaus nyob rau hauv cov xwm txheej hnyav.

Dab tsi yog ceramics thiab yog vim li cas

Ceramics tuaj yeem suav tias yog txhua yam uas tsis yog organic lossis hlau. Nws yog nws cov khoom uas tau muab los ua qhov xav tau rau kev sib txhuam ntawm lub tsheb nres ua haujlwm hauv cov xwm txheej nyuaj.

Lub disc nres muaj qhov zoo dua lwm tus, tab sis nws qhov tshwj xeeb yog qhov chaw me me. Thiab lub zog siab braking implies qhov kev tso tawm sai ntawm cov thermal zog loj. Raws li koj paub, lub zog yog proportional rau lub hwj chim thiab lub sij hawm uas nws tso tawm. Thiab ob qho tib si txiav txim siab lub braking efficiency ntawm lub tsheb.

Kev tso tawm ntawm lub zog tseem ceeb hauv qhov ntim tsawg hauv lub sijhawm luv luv, uas yog, thaum tshav kub tsis muaj sijhawm rau dissipate mus rau qhov chaw nyob ib puag ncig, raws li tib lub physics, ua rau muaj qhov kub thiab txias. Thiab ntawm no cov khoom siv ib txwm siv los ntawm cov khoom siv nres nres tsis tuaj yeem tiv taus. Kev siv cov ventilated disks tuaj yeem txhim kho cov thermal tswj nyob rau hauv lub sij hawm ntev, tab sis tsis txuag los ntawm lub zos overheating nyob rau hauv lub cheeb tsam. Cov ntaub qhwv cov ntaub ntawv cia li evaporates, thiab cov feem cuam tshuam ua rau ib puag ncig nplua, kev sib txhuam coefficient poob qis, thiab nres nres.

Ceramics raws li ntau yam inorganic tshuaj, feem ntau silicon carbide, tuaj yeem tiv taus kub ntau dua. Ntxiv mus, thaum sov so, lawv tsuas yog nkag mus rau qhov pom kev, muab qhov siab tshaj plaws coefficient ntawm kev sib txhuam.

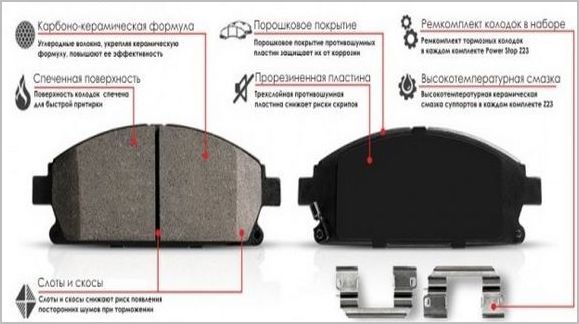

Yog tsis muaj kev txhawb zog, lub hauv ob sab yuav tsis tuaj yeem muaj lub zog txaus; rau qhov no, ntau cov fibers tau nkag mus rau hauv cov khoom sib xyaw. Feem ntau nws yog tooj liab shavings, carbon fiber yog siv rau kev ua si brakes. Cov khoom siv reinforcing yog tov nrog ceramics thiab ci ntawm qhov kub thiab txias.

Nyob ntawm qhov xwm txheej ntawm daim ntawv thov, cov qauv ntawm cov ntaub qhwv yuav txawv. Qhov no yog txiav txim siab los ntawm lub hom phiaj ntawm cov brakes, txoj kev, kev ua si los yog cov ntaub qhwv hnyav heev. Lawv muaj qhov sib txawv ntawm kev ua haujlwm kub thiab kev txwv tsis pub muaj peev xwm. Tab sis qhov dav dav yuav yog txhawm rau txhim kho kev ua haujlwm ntawm kev ua haujlwm nyuaj:

- kev sib txhuam coefficient stability;

- disc hnav minimization;

- txo cov suab nrov thiab kev vibration load;

- kev ua haujlwm siab thiab kev nyab xeeb ntawm cov khoom ntawm kev ua haujlwm siab.

Nrog kev siv cov ceramics, tsis yog tsuas yog cov ntaub qhwv, tab sis kuj discs. Nyob rau tib lub sijhawm, kev hnav ntau ntxiv tsis pom nyob rau hauv rooj plaub ntawm kev siv sib xyaw, cov ntaub qhwv ceramic tsis ua rau kom nrawm nrawm ntawm cov hlau thiab cam khwb cia hlau discs. Ceramic rotors (diss) yog qhov txawv los ntawm lub zog siab nyob rau hauv thermal loading tej yam kev mob, uas ua rau nws muaj peev xwm tsis ua rau lawv unacceptably loj, thiab kuj tsis tawm residual deformations thaum lub sij hawm cia txias. Thiab nrog cov cua kub zoo li no, txawm tias qhov txias txias ua rau qhov kub thiab txias hauv ib lub sijhawm tsawg.

Pros thiab cons ntawm tej hub nres

Nws twb tau hais txog qhov zoo ntawm ceramics, nws tuaj yeem ntxiv nrog tsis pom tseeb yam:

- xws li cov tshuab muaj qhov hnyav thiab qhov ntev nrog qhov sib npaug ntawm qhov ua tau zoo, uas txo qhov ntsuas qhov tseem ceeb ntawm kev ncua kev hloov pauv raws li qhov tsis muaj zog;

- tsis muaj kev tso tawm cov khoom tsis zoo rau hauv ib puag ncig;

- Nrog rau qhov nce ntawm qhov kub thiab txias, kev ua haujlwm ntawm tus brakes tsis txo qis, tab sis qhov nce ntxiv, uas qee zaum yuav tsum tau preheating;

- cov khoom siv ntxiv yog tsis raug rau qhov kub thiab txias corrosion;

- Cov khoom ntawm ceramics tau zoo kwv yees thiab programmed thaum xaiv ib daim ntawv qhia, uas ua rau nws muaj peev xwm tsim cov khoom zoo sib xws rau ntau yam kev siv;

- Kev sib txuas ntawm ferro-muaj cov khoom siv nrog cov ceramics tuaj yeem ua tau, nws tsis tas yuav siv tib lub discs rau cov ntaub ntawv ceramic;

- Cov khoom siv ceramic yog qhov ruaj khov heev thaum ua haujlwm hauv cov xwm txheej maj mam.

Nws tsis tuaj yeem ua yam tsis muaj minuses, tab sis tsis muaj ntau ntawm lawv tawm tsam keeb kwm ntawm qhov zoo:

- ceramic brakes tseem kim dua;

- tshwj xeeb tshaj yog zoo compositions yuav tsum tau preheating, txij li thaum lub coefficient ntawm kev sib txhuam txo nrog txo kub;

- nyob rau hauv ib qho kev sib xyaw ua ke ntawm cov xwm txheej, lawv tuaj yeem tsim qhov nyuaj-rau-tshem tawm creak.

Nws yog tseeb tias ceramic nres qhov tsis muaj lwm txoj hauv kev tsav tsheb thiab kev ua si. Hauv lwm qhov xwm txheej, lawv tus nqi siab ua rau ib tus xav txog qhov tsim nyog ntawm lawv siv.