Nres pads. Koj yuav tsum paub dab tsi

Nyob rau hauv cov tsheb niaj hnub no, ob hom nres mechanism yog siv - disc thiab nruas. Nyob rau hauv ob qho tib si, txoj kev sib txhuam ntawm braking yog siv, nyob rau hauv uas lub deceleration ntawm kev sib hloov ntawm lub log tshwm sim vim muaj kev cuam tshuam ntawm kev sib txhuam khub. Nyob rau hauv xws li ib tug khub, ib qho ntawm cov khoom yog txav tau thiab tig nrog lub log, lwm qhov yog nyob ruaj ruaj. Cov khoom txav txav yog lub nres disc lossis nruas. Cov khoom ruaj khov yog lub nres nres, uas yuav tau tham hauv kab lus no.

Thaum lub sij hawm braking, kua siab yog tsim nyob rau hauv lub hydraulic system los yog compressed cua yog siv pneumatics raws li ib tug tsav. Lub siab yog pauv mus rau lub tog raj kheej ua haujlwm (lub log), thiab lawv cov piston, txav mus rau pem hauv ntej, ua haujlwm ntawm cov nres nres. Thaum cov ntaub qhwv raug nias tawm tsam lub disk lossis lub nruas rotating nrog lub log, kev sib txhuam quab yuam tshwm sim. Cov ntaub qhwv thiab disc (nruas) ua kom sov. Yog li, lub zog kinetic ntawm lub tsheb lub zog hloov mus rau hauv thermal zog, qhov ceev ntawm kev sib hloov ntawm lub log yuav txo qis thiab lub tsheb qeeb.

Колодки для тормозных механизмов дискового и отличаются формой. В дисковых тормозах они плоские, в барабанных выполнены в виде дуги. Форму определяет поверхность, с которой колодки контактируют — плоская боковая поверхность диска либо внутренняя цилиндрическая рабочая поверхность барабана. В остальном принципиальных отличий в их конструкции нет.

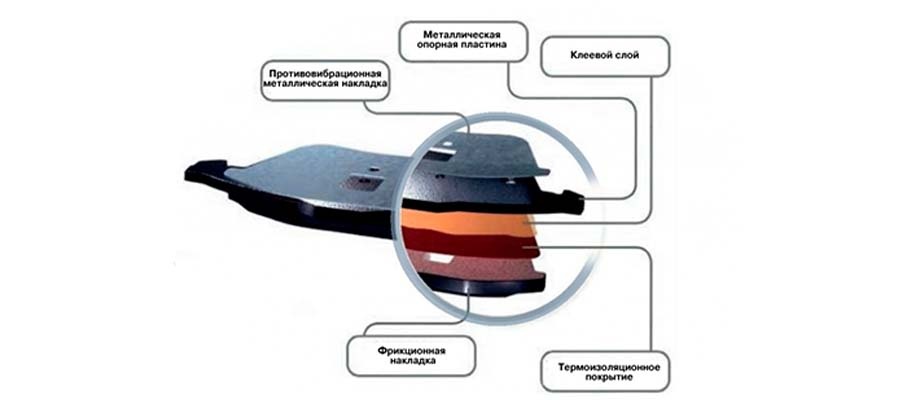

Lub hauv paus yog tsim los ntawm cov hlau bearing phaj. Nyob rau sab tsis ua hauj lwm, nws muaj damping primer los dampen vibrations thiab suab nrov. Hauv qee qhov kev tsim, lub damper tuaj yeem ua rau hauv daim ntawv ntawm lub phaj hlau tshem tau.

Kev sib txhuam hauv ob sab sib cuam tshuam ncaj qha nrog lub disc lossis nruas, uas txuas nrog lub hauv paus nrog cov nplaum tshwj xeeb lossis nrog rivets. Nws tshwm sim tias cov hauv ob sab phlu tuaj yeem tshem tau, tab sis feem ntau qhov thaiv tau hloov tag nrho.

Cov hauv ob sab phlu yog qhov txaus nyiam tshaj plaws ntawm lub nres nres. Braking efficiency, nrog rau kev pab cuam lub neej thiab tus nqi ntawm lub ncoo nws tus kheej, feem ntau nyob ntawm nws cov kev txwv thiab kev ua haujlwm.

Между фрикционным слоем и опорной пластиной имеется термоизоляционная прослойка. Она предохраняет от чрезмерного нагрева, а от закипания.

Feem ntau, chamfers thiab ib qho los yog ib txheej ntawm qhov qhib yog ua nyob rau sab ua haujlwm ntawm lub ncoo. Chamfers txo kev vibration thiab suab nrov, thiab cov slots pab tshem tawm cov plua plav, thiab kuj txhim kho cov cua kub dissipation.

Ib txheej txheej txheej feem ntau yog siv rau sab saum toj ntawm cov txheej txheem sib txhuam kom nrawm dua rau qhov tsis sib xws.

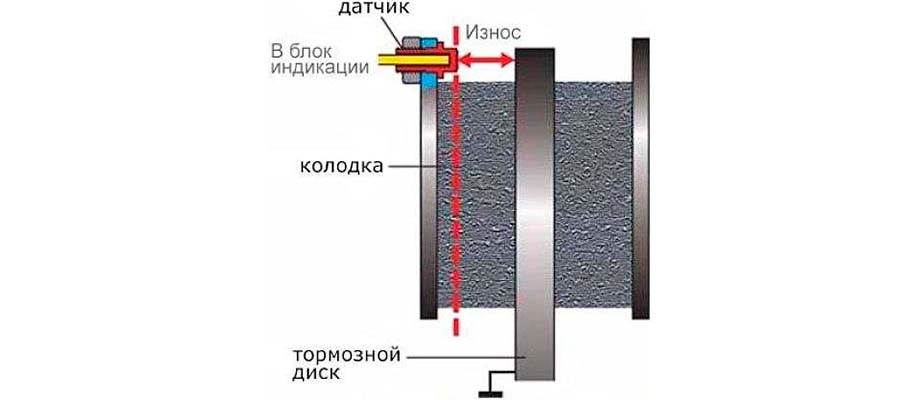

Txhawm rau pab tus neeg tsav tsheb nkag siab tias qhov thaiv tau mus txog qhov tseem ceeb ntawm kev hnav, ntau lub tuam txhab muab nws nrog cov cuab yeej siv hluav taws xob, uas yog cov phaj hlau ruaj khov rau qhov kawg. Thaum cov txheej txheem kev sib txhuam hnyav hnyav, lub npoo ntawm lub phaj yuav pib kov lub nres disc thiab emit ib tug yam ntxwv nrov squeal.

Tsis ntev los no, los tswj cov qib ntawm kev hnav ntawm cov ntaub qhwv, cov khoom siv hluav taws xob siv hluav taws xob, thaum tshwm sim, cov teeb pom kev zoo ntawm lub dashboard teeb. Lawv tuaj yeem yog sab nraud lossis built-in. Hauv qhov thib ob, hloov pauv, koj yuav tsum tau yuav cov ntaub qhwv nrog kev sib xyaw ua ke.

Lub ntsiab yuav tsum tau muaj rau hauv ob sab phlu yog kom txaus braking kev ua tau zoo nyob rau hauv txhua txoj kev, nrog rau cov av nkos thiab high humidity. Nws yog cov dej noo uas nthuav tawm qhov teeb meem loj tshaj plaws rau kev ua haujlwm ib txwm muaj ntawm tus nres nres, ua si lub luag haujlwm ntawm cov roj nplua nyeem thiab txo cov coefficient ntawm kev sib txhuam.

Cov ntaub qhwv yuav tsum khaws lawv cov khoom ua haujlwm hauv huab cua hnyav, tiv taus qhov kub thiab txias hloov pauv, uas thaum lub sij hawm kev sib txhuam tuaj yeem ncav cuag 200 ... 300 ° C thiab ntau dua.

Cov yam ntxwv suab nrov kuj tseem ceeb heev. Kwv yees li ib puas xyoo dhau los, thaum disc brakes tau tsim, cov ntaub qhwv tsis muaj cov ntaub qhwv thiab kev sib txhuam ntawm cov hlau ntawm cov hlau thaum lub sij hawm braking tau nrog ib tug txaus ntshai rattle. Nyob rau hauv niaj hnub brakes, qhov teeb meem no yog xyaum tsis tuaj, txawm hais tias cov ntaub ntawv tshiab yuav squeak ib pliag kom txog thaum lawv hnav.

Lwm qhov kev xav tau tseem ceeb rau cov ntaub qhwv ntsej muag yog tus cwj pwm maj mam rau tus nres disc (nruas). Ib qho kev sib txhuam ntawm cov ntaub ntawv uas yog mos heev yuav txo tau lub braking quab yuam tsim los ntawm kev sib txhuam, thiab ib qho kev sib txhuam uas nyuaj heev yuav sai sai "noj" lub disc, uas raug nqi ntau dua li cov ntaub qhwv.

Tsis tas li ntawd, ib qho kev sib txhuam nyuaj heev tuaj yeem ua tiav tag nrho cov kev sib hloov ntawm lub log, thaum lub tsheb tseem tsis tau qeeb txaus. Hauv qhov xwm txheej no, lub tsheb tuaj yeem mus skidding thiab ua tsis tau.

Kev sib txhuam hauv cov tsheb, raws li txoj cai, muaj kev sib txhuam coefficient ntawm 0,35 ... 0,5. Qhov no yog qhov zoo tshaj plaws tus nqi uas tso cai rau braking kom zoo nyob rau hauv lub nroog txoj kev thiab lub teb chaws txoj kev thiab nyob rau tib lub sij hawm yuav pab khaws cia lub brake disc. Muaj cov ntaub qhwv nrog cov coefficient ntau dua ntawm kev sib txhuam, tab sis lawv feem ntau yog npaj rau kev ua si tsheb uas yuav tsum tau qeeb qeeb thiab nrawm heev.

Nyob rau hauv ancient sij hawm, asbestos tau dav siv nyob rau hauv zus tau tej cov kev sib txhuam linings. Txawm li cas los xij, nws tau pom tias cov plua plav asbestos muaj cov khoom carcinogenic, yog li cov khoom siv no tau raug txwv tag nrho hauv European Union xyoo 2005. Lwm lub tebchaws tau maj mam ua raws li lawv tus yam ntxwv. Vim li no, cov pawm nres uas muaj cov asbestos tau dhau los ua qhov tsis tshua muaj thiab, tau kawg, kev teeb tsa ntawm cov khoom siv no yuav tsum zam.

Asbestos tau hloov los ntawm cov khoom sib xyaw uas muaj qee zaum 15-20 feem. Cov tuam txhab lag luam loj lawv tus kheej tsim cov ntaub ntawv sib txhuam, sib zog ua kom tiav cov khoom ua tau zoo tshaj plaws.

Txog rau tam sim no, muaj peb hom tseem ceeb hauv ob sab phlu rau nres nres - organic, hlau-muaj thiab ceramic.

Cov organic feem ntau yog tsim los ntawm graphite nrog kev sib ntxiv ntawm cov binders thiab kev sib txhuam-txhim kho cov khoom - polymers, fiberglass, tooj liab lossis tooj liab shavings, thiab lwm yam ntaub ntawv. Txij li thaum muaj pes tsawg leeg muaj cov hlau me me (txog 30%), cov khoom no tseem hu ua low-metal (low-metallic).

Pads ntawm hom no yog dav siv nyob rau hauv lub tsheb tom qab muag khoom, lawv zam Frost zoo thiab muaj tus nqi txaus nyiam. Ntawm qhov tod tes, organic rubbers kuj yog mos, lawv tsis muaj qhov hnyav hnyav thiab tsis zoo nyob rau hauv kev ntxhov siab hnyav.

Kev suav nrog cov tooj liab, hlau lossis lwm yam hlau tseem ceeb hauv cov khoom siv sib txhuam zoo txhim kho cov cua sov hloov mus, yog li cov ntaub qhwv no tuaj yeem tiv taus cua sov zoo, piv txwv li, thaum tsav tsheb hnyav. Cov ntaub ntawv uas muaj hlau tsis tshua muaj rau lawv tus kheej hnav, tab sis lub teeb tshem tawm cov nres nres ntau dua thiab muaj suab nrov me ntsis. Ntau tus xav txog qhov kev xaiv no yog qhov zoo rau kev siv ntawm feem ntau cov neeg nrog caij tsheb.

Ceramic-raws li linings yog heev hnav-resistant thiab ua hauj lwm zoo nyob rau hauv muaj zog cua sov, yog li lawv siv yog tsim nyog nyob rau hauv kev sib tw tsheb, qhov uas tam sim no braking yuav ua rau cua sov mus txog 900-1000 ° C. Txawm li cas los xij, lawv tsis haum rau kev tsav tsheb ib txwm nyob ib puag ncig lub nroog lossis lub tebchaws mus ncig, vim lawv xav tau preheating txog 200 ° C. Thiab unheated ceramics yuav tsis tuaj yeem qhia lawv qhov zoo tshaj plaws, tab sis lawv tuaj yeem ua kom nrawm nrawm ntawm lub nres nres. Tsis tas li ntawd, tus nqi ntawm cov ntaub ntawv ceramic yog siab dhau.

Yog hais tias qhov kev ncua deb ntawm lub braking tau nce, lub squeal ntawm lub coj qhia tau hnov, lub tog raj kheej nres ua hauj lwm yog jammed, lub caliper yog daig, ces nws yog lub sij hawm los hloov cov ntaub. Txawm li cas los xij, nws yog qhov zoo dua los saib xyuas cov xwm txheej ntawm lub tshuab nres tsheb thiab cov pawm, tsis tas tos cov teeb liab. Koj tuaj yeem kwv yees qhov degree ntawm hnav ntawm cov ntaub qhwv los ntawm kev saib ntawm lub qhov rais hauv caliper. Yog hais tias 1,5 ... 2 hli yog sab laug ntawm kev sib txhuam txheej, cov ntaub qhwv yuav tsum tau hloov. Thiab ntawm chav kawm, koj tsis tuaj yeem nqa qhov teeb meem mus rau qhov ua tiav ntawm lub hauv ob sab phlu, vim qhov no lub hauv paus hlau ntawm lub ncoo yuav ua rau lub nres nres sai sai.

rau kev hloov pauv, koj yuav tsum coj mus rau hauv tus account hom tsheb, nws qhov loj, lub zog ntawm lub cav, kev ua haujlwm, kev tsav tsheb.

Xaiv cov ntaub qhwv uas zoo ib yam li cov ntaub qhwv uas koj tab tom hloov. Qhov no yuav ua kom ceev thiab txhim kho lawv cov kev sib tsoo, tshwj xeeb tshaj yog tias cov disc (nruas) muaj pob (lub xub pwg nyom).

Rau siab tshaj plaws compatibility, nws yog qhov zoo dua uas cov ntaub qhwv thiab disc yog los ntawm tib lub chaw tsim khoom.

Nco ntsoov hloov tag nrho cov pawm ntawm ob lub log ntawm tib lub qag. Txwv tsis pub, tus cwj pwm ntawm lub tshuab thaum lub sij hawm braking tej zaum yuav unpredictable.

Cov khoom lag luam muaj peev xwm muab faib ua peb pawg:

- 1. Thawj, uas yog, cov uas tau nruab rau ntawm cov tshuab tawm hauv cov kab sib dhos. Lawv tuaj yeem raug nqi kim, tab sis ntawm qhov tod tes, koj tau lees tias yuav tau txais ib feem uas nws qhov zoo yog tswj tsis tau tsuas yog los ntawm cov chaw tsim khoom ncaj qha, tab sis kuj yog los ntawm cov kws tsim hluav taws xob hauv qab nws lub npe nws tsim. Yog li, koj tuaj yeem paub tseeb tias cov khoom ua tau raws li cov yam ntxwv tshaj tawm.

2. Analogues (lub npe hu ua tom qab muag khoom) yog cov khoom tsim los ntawm tib lub tuam txhab raws li cov khoom qub, tab sis raug muag raws li lawv lub npe. Tej zaum lawv yuav muaj qee qhov sib txawv ntawm cov lus tshaj tawm. Xyoo 1999, Lub Tuam Txhab Nyiaj Txiag rau Tebchaws Europe xav kom cov tuam txhab tsim khoom tsis yog thawj qhov chaw nres tsheb kom tau raws li qhov yuav tsum tau ua ntawm automaker tsawg kawg yog 85%. Txwv tsis pub, cov khoom tsis raug tso cai nyob rau hauv European lag luam. Qhov kev sib haum xeeb no yog qhia los ntawm ECE R90 cim.

Hais txog tus nqi, analogues tuaj yeem nyob ze rau qhov qub, tab sis feem ntau pheej yig dua los ntawm 20 ... 30%.

Cov coefficient ntawm kev sib txhuam rau cov ntaub ntawv analog yog qis dua rau cov khoom qub, thiab feem ntau yog 0,25 ... 0,4. Qhov no, ntawm chav kawm, yuav cuam tshuam qhov ceev ntawm lub brakes thiab qhov ntev ntawm lub braking deb.

3. Cov khoom tsim rau cov teb chaws tsim. Nyob rau hauv pawg no, koj tuaj yeem nrhiav cov ntaub ntawv pheej yig, tab sis lawv qhov zoo yog muaj hmoo zoo li leej twg. Cov pawm pheej yig tsis zoo li yuav kav ntev, tab sis lawv tuaj yeem ua rau lub nres nres. Yog li cov nyiaj khaws cia no tuaj yeem ua rau tsis ntseeg siab, tshwj xeeb tshaj yog tias koj nco qab tias peb tab tom tham txog kev ruaj ntseg.

Nws yog qhov zoo dua los tig mus rau, qhov no koj yuav tsis poob rau ib qho fake, uas muaj ntau heev, tab sis lawv tau faib feem ntau hauv khw thiab khw muag khoom me.