Bars yog dab tsi?

Txheem

Hlau | |

| Hlau yog ib qho alloy ntawm hlau, carbon thiab lwm yam khoom, feem ntau pheej yig thiab dav muaj. Cov pas nrig feem ntau yog tsim los ntawm cov hlau, uas tuaj yeem siv tau rau ntau yam kev siv. |

Cov hlau | |

| Cov pa roj carbon steel yog cov hlau uas lub ntsiab alloying yog carbon. Nws yog ib qho nyuaj dua li cov hlau tsis tu ncua, tab sis tsis tshua muaj ductile, txhais tau tias nws nyuaj rau kev tsim cov duab uas xav tau thiab yuav ua rau tawg lossis tawg dua li nws yuav khoov. |

| Cov pa roj carbon tsawg (0.30–0.59%), tseem hu ua "cov hlau me me", "cov pa roj carbon yooj yim" lossis "qeb qis steel", feem ntau muaj nyob ntawm tus nqi pheej yig thiab muaj cov ntsiab lus qis dua, ua rau nws yooj yim dua (yooj yim rau khoov) tab sis qaug zog. |

| Cov pa roj carbon ntau (0.6-0.99%), tseem hu ua "cov hlau zoo", tuaj yeem kho cua sov kom ntxiv dag zog. Cov lej ntawm lwm cov ntsiab lus nyob rau hauv high carbon steel alloy tuaj yeem muaj qhov cuam tshuam tsis zoo thiab ua rau brittleness ntawm kev ua haujlwm kub. Cov ntsiab lus ntawm sulfur nyob rau hauv cov kab mob yog qhov teeb meem tshwj xeeb. |

| Ultra high carbon steel (1.0-2.0%) yog qhov tawv heev thaum tempered thiab tuaj yeem tiv taus siab hnav thiab puas. |

hlau alloy | |

| Alloy steel feem ntau yog hais txog cov hlau tsis tshua muaj hlau, cov hlau uas tau raug alloyed nrog cov ntsiab lus dav dav hauv cov khoom loj, txhim kho cov khoom siv kho tshuab. |

High alloy boron hlau | |

| Qhov no yog steel hardened los ntawm alloying nrog boron. Boron yog ib qho kev lag luam tab sis muaj txiaj ntsig zoo alloying uas muab kev txhim kho tiv thaiv xeb, corrosion thiab puas. Qhov sib ntxiv ntawm boron kuj tseem siv tau rau cov hlau tawv tawv, tshwj xeeb tshaj yog cov hlau tsis muaj carbon steel, uas tsis tuaj yeem kho cua sov. Txawm li cas los xij, boron quenching tuaj yeem txo ductility; Qhov no txhais tau hais tias cov cuab yeej hnav yuav tawg ntau dua li khoov thiab tsis tuaj yeem khaws cia. |

steel caij nplooj ntoos hlav | |

| Tsawg alloy tsawg carbon steel nrog siab tawm los muaj zog. Lub zog yield zog txhais tau hais tias cov khoom tsim los ntawm cov hlau no muaj peev xwm rov qab mus rau lawv cov qauv qub tom qab kev deformation tseem ceeb (twisting lossis khoov). Hom hlau no yog qhov zoo tshaj plaws siv rau hauv tes thiab pry tuav, uas yog tsim los muab qee qhov kev tiv thaiv. |

Forged hlau | |

| Thaum lub sij hawm forging txheej txheem, steel yog txuas mus rau saum npoo ntawm ib tug rauj thiab poob los ntawm ib qhov siab mus rau ib tug workpiece kom deform nws mus rau hauv cov duab ntawm ib tug tuag (ib lub cuab tam siv thaum lub sij hawm forging txiav los yog nias cov hlau rau hauv lub siab xav). Forged steel yog yuav luag ib txwm muaj zog dua cam khwb cia los yog machined hlau vim hais tias cov txheej txheem forging aligns lub grain qauv nrog cov duab ntawm lub cuab tam. Hom hlau no zoo tshaj plaws siv rau hauv cov pas nrig tsim los rau lub zog loj xws li cov pas nrig, cov pas nrig loj thiab cov pas nrig gorilla. |

Titan | |

| Titanium yog lub teeb thiab muaj zog, ua rau nws yog cov hlau nrov rau cov cuab yeej tes. Titanium yog zoo tshaj plaws siv nyob rau hauv molding rods thiab ke rods. Vim lawv lub teeb yuag, cov cuab yeej titanium yog nrov txawm tias cov neeg cawm siav, tab sis lawv kim dua thiab yooj yim heev, ua rau lawv tsis muaj zog. Kev lag luam titanium muaj tib lub zog tensile raws li qib qis steel alloys, tab sis hnyav 45% tsawg dua ib phaus. |

txhuas | |

| Aluminium yog pheej yig, lub teeb hlau hlau nrog lub ntom ntom nrog lub ntom ntom thiab txhav uas muaj li peb zaug tsawg dua li cov hlau sib xyaw. Muaj qee qhov tshwj xeeb, aluminium yog mos dhau los siv rau hauv cov pas nrig uas xav tau lub zog tensile siab. Ib qho kev zam yuav yog qhov xwm txheej thaum lub pas nrig tsis sib nqus tshwj xeeb yog xav tau. |

Cov txheej txheem tsim khoom | |

| npau taws"Tempering" yog ib txoj kev siv los ua kom tawv nqaij. Txij li thaum muaj ntau txoj kev hardening siv nyob rau hauv lub cuab tam yuav ua rau cov alloy brittle, tempering yog siv los txhim kho ductility. Cov cuab yeej tsim los ua kom muaj zog, xws li khawb cov pas nrig, yog hardened ntawm qhov kub thiab txias, thaum cov cuab yeej tsim los khaws qee qhov "caij nplooj ntoos hlav", xws li tes rods, yog hardened ntawm kub dua. |

| Thaum tempered, alloy steels rov qab rhuab thiab txias, uas tso cai rau lub internal alloying ntsiab reacts nyob rau hauv cov hlau - qhov no tsim "intermetallic theem" hu ua "precipitations" uas ua rau kom lub brittleness ntawm lub alloy. |

| tawvThaum lub sij hawm quenching, steel yog rhuab mus rau ib tug normalization kub (760 + ° C) thiab quenched nyob rau hauv dej, roj los yog cua txias. |

| Thaum cov hlau alloy yog cua sov siab tshaj 760 ° C, carbon atoms tsiv mus rau ib qho chaw hauv nruab nrab hauv cov qauv atomic ntawm cov hlau. Thaum lub alloy yog ces quenched, cov pa roj carbon atoms nyob rau hauv qhov chaw, ua rau ib tug nyuaj steel. |

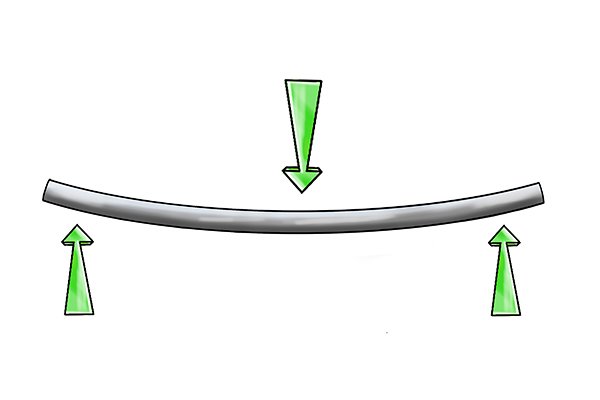

Lub zog tensile yog dab tsi? | |

| Lub zog tensile yog qhov load ntawm cov hlau tuaj yeem tiv taus yam tsis muaj kev tawg, tawg, lossis tawg. Lub zog tensile siab txhais tau hais tias cov khoom siv tuaj yeem tiv taus qhov siab ntawm kev ntxhov siab (xws li khoov) ua ntej tsis ua haujlwm, thaum lub zog tensile qis txhais tau hais tias cov khoom tawg yooj yim thaum thauj khoom. |