Cold welding rau hlau - cov lus qhia rau kev siv

"Cold welding" lossis "Fast steel" yog ib qho cuab yeej rau gluing hlau, yas, ntoo thiab lwm qhov chaw. Nws yuav tsum tau muab sau tseg tias nws tsis muaj dab tsi ua nrog vuam, txij li thaum vuam txias yog txheej txheem thev naus laus zis uas cov hlau txuas ruaj khov rau ib leeg vim yog kev taw qhia siab thiab deformation yam tsis muaj qhov kub thiab txias. Kev sib txuas tshwm sim nyob rau theem ntawm molecular bonds. Zoo, "txias vuam" kua nplaum tau ntev tau hu ua qhov ntawd vim qhov tseeb tias cov seams nyob rau saum npoo, zoo li tom qab vuam kub.

Yog li, "Cold welding" yog cov nplaum nplaum, uas suav nrog:

- epoxy cob;

- tawv tawv;

- hloov kho additives.

Epoxy resins tsis tsim ib daim ntawv cog lus muaj zog thaum kho, thiab yog li ntawd cov plasticizers ntxiv rau lawv los pab tiv thaiv kev poob siab thiab kev co, uas yog ib qho tseem ceeb heev thaum nws los kho lub cev los yog hauv qab ntawm lub tsheb. Tsis tas li ntawd, lub zog ntawm kev sib koom ua ke yog nce los ntawm kev ntxiv cov khoom siv hlau raws li txhuas lossis hlau.

Cov cuab yeej no yog muag nyob rau hauv daim ntawv ntawm cov hlab, ib tug ntawm cov uas muaj ib tug nplaum puag, thiab lwm yam muaj ib tug hardener. Los yog nyob rau hauv daim ntawv ntawm putty - ob-txheej cylindrical tuav.

Cov lus qhia rau kev siv vuam txias

Ua ntej gluing hlau qhov chaw, lawv nto yuav tsum tau ntxuav tag nrho cov av thiab hmoov av. Tom qab ntawd, lawv yuav tsum tau degreased los ntawm txhua txoj kev muaj - hnyav, cawv, cologne.

Yog tias cov vuam txias yog nyob rau hauv cov hlab, ces koj yuav tsum tau nyem cov kua nplaum uas yuav tsum tau los ntawm txhua lub raj rau hauv ib lub thawv thiab sib tov zoo kom txog thaum lub homogeneous loj tsim.

Nws yog ib qho tsim nyog los npaj qhov sib tov rau hauv qhov chaw cua, vim tias cov epoxy resin vapors tuaj yeem ua rau cov qog nqaij hlav hauv caj pas thiab qhov ntswg.

Nws yog ib qho tsim nyog yuav tau siv cov txiaj ntsig tau sai li sai tau - nyob ntawm cov chaw tsim khoom, tsis pub dhau 10-50 feeb. Ntawd yog, yog tias yuav tsum tau ua haujlwm kho ntau, ces nws yog qhov zoo dua los siv vuam hauv cov khoom me me, txwv tsis pub nws yuav qhuav thiab siv tsis tau.

Tom qab ntawd koj tsuas yog siv cov putty rau ob qhov chaw, nyem lawv me ntsis thiab tshem tawm cov kua nplaum ntau dhau. Cov chaw sib txuas ua ke zoo heev thiab tsis tas yuav tsum tau nias tawm tsam ib leeg nrog tag nrho cov quab yuam. Tsuas yog tawm ntawm qhov yuav tsum tau kho kom txog thaum cov nplaum nplaum. Qhov no yuav siv sijhawm kaum feeb mus rau ib teev.

Cov kua nplaum tag nrho hardens nyob rau hauv ib hnub, yog li tawm ntawm ib sab kom txog thaum nws tag nrho hardens.

Putty "Cold welding"

Cold welding, uas tuaj nyob rau hauv daim ntawv tuav, nws tseem hu ua putty, yog siv los kaw cov kab nrib pleb thiab kaw qhov. Hauv nws qhov sib xws, nws zoo li plasticine, yog li nws yog qhov zoo rau kev ua haujlwm zoo li no.

Koj yuav tsum ua haujlwm nrog nws raws li hauv qab no:

- huv si thiab degrease qhov chaw yuav tsum tau sib koom;

- txiav tawm qhov yuav tsum tau ntawm putty nrog ib tug clerical riam;

- knead lub putty zoo kom txog thaum ib homogeneous yas loj (tsis txhob hnov qab hnav hnab looj tes roj hmab);

- lub putty tuaj yeem ua kom sov thaum kneading - qhov no yog qhov qub;

- siv rau ib feem;

- mus rau theem txheej, koj tuaj yeem siv spatula, nws yuav tsum tau moistened kom lub putty tsis lo rau nws;

- tawm ntawm qhov ib leeg kom txog rau thaum lub putty hardens.

Qee cov craftsmen pom zoo kom nias qhov chaw kom ua ke nrog lub clamp los yog lwm yam.

Txawm hais tias nws yog, tab sis tom qab solidification, cov roj yuav nyuaj li pob zeb. Thov nco ntsoov tias nws yooj yim heev kom tshem tawm cov kua nplaum los yog putty nrog cov cua sov hlau los yog riam kub.

Cov lus pom zoo rau kev siv cov vuam txias

Raws li peb tuaj yeem pom, kev vuam txias yog muag hauv daim ntawv ntawm ob lub ntsiab lus nplaum, lossis hauv daim ntawv ntawm putty, nco txog cov yas hauv nws qhov sib xws, uas sai sai hardens. Rau qhov zoo tshaj plaws, koj yuav tsum coj mus rau hauv tus account lub chaw tsim tshuaj paus cov lus pom zoo, yog li cov kua nplaum yog siv rau kev koom tes los yog nteg nto nyob rau hauv sab saum toj ntawm txhua lwm yam, tab sis lub putty yog haum rau tee los yog kaum pob qij txha. Nws kuj yog ib qho zoo heev rau sealing ntau lub qhov thiab cov kab nrib pleb.

Txhawm rau txhim kho cov nyhuv lossis thaum nws los txog rau thaj tsam loj ntawm qhov chaw kho, lub putty yog siv nrog lub zog mesh lossis fiberglass thaj ua rau thaj.

Nyob rau hauv cov ntaub ntawv ntawm kev tawg, lawv qhov kawg yuav tsum tau drilled kom cov kab nrib pleb tsis loj hlob ntxiv. Lawv kuj ua zoo ib yam thaum kho cov kab nrib pleb ntawm lub tsheb, uas peb twb tau tham txog ntawm peb lub vev xaib Vodi.su.

Thov nco ntsoov tias txias welding putty kuj siv tau los ua kom cov dents. Koj tuaj yeem sau cov dents nrog cov kua nplaum, tos kom qhuav, thiab ua kom nws tawm nrog me me spatula.

Cold welding manufacturers

Yog tias peb tham txog cov tuam txhab tshwj xeeb thiab cov npe, peb xav pom cov npe hauv qab no.

Abro Hlau - Cov khoom lag luam Asmeskas ntawm cov qib siab tshaj plaws. Muag nyob rau hauv daim ntawv tuav ntawm ob lub ntsiab lus putty, ntim rau hauv cov thawv yas cylindrical. Qhov hnyav ntawm ib lub raj yog 57 grams. Cov muaj pes tsawg leeg ntawm epoxy nplaum muaj xws li, ntxiv rau plasticizers thiab hardener, hlau muab tub lim, kom Abro Steel siv tau los kho:

- roj tank;

- cua txias radiators;

- roj lauj kaub;

- mufflers;

- thaiv taub hau thiab lwm yam.

Nws kuj tseem tuaj yeem siv tau hauv lub neej niaj hnub, piv txwv li, rau kev sib khi qhov hauv cov hlau-yas lossis hlau kav, gluing thoob dej yug ntses, kho cov cuab yeej thiab ntau ntxiv. Glue muab kev sib txuas zoo heev ntawm qhov kub ntawm qhov kub ntawm 50 degrees mus rau ntxiv rau 150 degrees. Nws yuav tsum tau siv raws li cov lus qhia saum toj no.

Poxypol - kua nplaum putty, uas tuaj yeem siv tau ntau txoj hauv kev. Nws hardens sai heev thiab muab qhov muaj zog tshaj adhesion. Kho qhov chaw tuaj yeem drilled thiab txawm threaded.

Pob Zeb Diamond Xovxwm - Tsim tshwj xeeb rau kev kho tsheb. Lawv tuaj yeem kho cov kab nrib pleb hauv lub tank, muffler, lub tog raj kheej thaiv. Tsis tas li ntawd, nws yog siv los ruaj ntseg nameplates - cim ntawm cov chaw tsim tshuaj paus. Nws muaj epoxy resins thiab muab tso rau ntawm lub hauv paus ntuj lossis hlau.

Koj tuaj yeem sau npe rau ntau lub npe nrov: Blitz, Skol, Monolith, Forbo 671. Tag nrho cov ntawm lawv muab kev sib txuas txhim khu kev qha, txawm nyob hauv dej. Yog tias koj tab tom kho qhov chaw hauv txoj kev no, thiab koj xav kom kev sib txuas kom ntev li ntev tau, ua raws li cov cai yooj yim no:

- Thaum rhuab, cov kua nplaum yuav qhuav sai dua thiab muab cov adhesion zoo, yog li siv lub tsev plaub hau tshuab;

- Cov chaw uas sov sov thaum lub sijhawm ua haujlwm tshaj 100 degrees tsis pom zoo kom kho nyob rau hauv txoj kev no - cov kua nplaum tuaj yeem tiv taus txog li 150 degrees ntawm tshav kub rau lub sijhawm luv luv, tab sis nws tawg nrog lub sijhawm ntev;

- tsis pom zoo siv qhov kub qis dua tsib degrees Celsius;

- khaws cia txias vuam zoo dua ntawm chav tsev kub kom deb ntawm lub hnub ncaj qha.

Yog tias koj yuav txias vuam rau kev xav tau kev lag luam, ces koj tuaj yeem nrhiav tau ntau lub ntim ntim. Piv txwv li, Metalox txias welding tuaj nyob rau hauv ib nrab-liter poom thiab ib tug xws li yog txaus los kho 0,3 square meters. nto. Kuj tseem muaj qhov ntim ntau dua - hauv cov thoob hlau ntawm 17-18 kilograms.

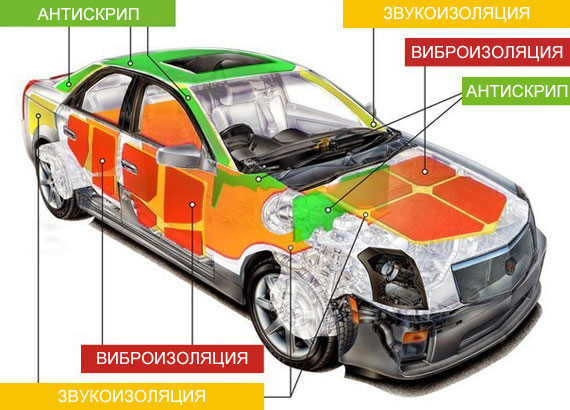

Raws li kev xyaum thiab kev paub ntawm ntau tus neeg tsav tsheb ua tim khawv, kev vuam txias muab kev sib txuas ruaj khov. Tab sis tsis txhob hnov qab tias qhov no yog ib hom ntawm epoxy kua nplaum, txawm tias nrog ntxiv ntawm cov hlau muab tub lim. Yog li ntawd, peb yuav tsis pom zoo kom txias vuam rau kev kho cov khoom tseem ceeb ntawm lub tsheb thiab kev sib dhos.

Cov yeeb yaj kiab nrog cov lus pom zoo thiab lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm vuam txias.

Loading…