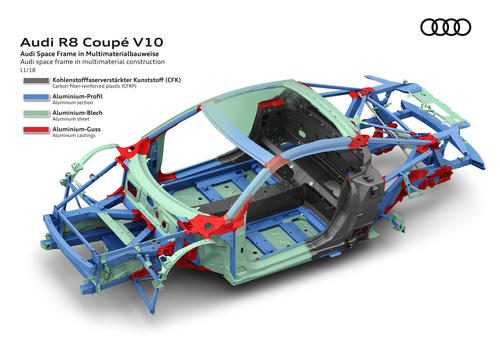

ASF – Audi Space Frame

ASF feem ntau yog kaw ntu extruded seem txuas rau ib leeg los ntawm kev txhaj tshuaj molded sib dhos. Raws li Audi, qhov rov ua dua yog tsib npaug ntawm cov hlau.

Tag nrho lub zog xav tau rau kev tsim khoom yog 152-163 GJ piv rau 127 GJ rau cov hlau zoo sib xws.

Extruded

Yeej, lawv yog profiled nrog lub thawv-zoo li profile. Cov alloys siv tsis tau tshaj tawm Al-Si alloys nrog Si cov ntsiab lus ntau dua 0,2% los xyuas kom meej flowability thiab nag lossis daus hardening thaum lub sij hawm kev laus.

nplooj ntawv

Siv rau cov khoom siv thauj khoom, slabs, ru tsev thiab firewalls, lawv suav txog 45% ntawm cov qauv qhov hnyav. Lawv thickness yog 1.7-1.8 npaug ntau dua li cov hlau. Cov alloy siv 5182 nyob rau hauv lub xeev T4 (ntau deformable) nrog ib tug elastic txwv ntawm 140-395 MPa. Nws tuaj yeem txhawb nqa txawm tias muaj tsawg dua 7% magnesium vim muaj lwm cov kab mob.

Cam khwb cia units

Lawv siv nyob rau hauv cov cheeb tsam uas muaj kev ntxhov siab loj tshaj plaws.

Lawv tau ua tiav siv cov txheej txheem hu ua VACURAL, uas suav nrog kev txhaj tshuaj txhuas ua kua rau hauv lub tshuab nqus tsev kom tau txais:

Zoo thiab uniformity, porosity tsawg heev los lav lub siab txhua yam khoom ua ke nrog lub toughness yuav tsum tau rau qaug zog kuj;

Zoo weldability xav tau rau kev koom nrog cov profiles.

Cov txheej txheem kev sib txuas

Muaj ntau txoj kev siv:

MIG welding: siv rau cov ntawv nyias thiab rau kev sib koom ua ke rau ib qho profile;

Spot welding: rau cov ntawv hlau tsis siv tau nrog cov ntsia hlau pliers;

Stapling: ntawm qhov tseem ceeb thib ob los ntawm qhov kev pom ntawm qhov pom vim txo qhov tsis zoo li qub; siv los koom nrog cov ntawv txheeb kom ntxiv dag zog rau qhov chaw;

Riveting: siv nyob rau hauv bearing ntsiab nrog ib tug loj nto; nrog tib lub thickness, nws muaj qhov tsis kam ntawm ntau tshaj 30% piv rau vuam; nws kuj muaj qhov zoo ntawm kev xav tau lub zog tsawg dua thiab tsis hloov cov qauv ntawm cov khoom siv.

Cov nplaum nplaum: siv rau cov iav ruaj khov, hauv qhov rooj thiab lub kaus mom pob qij txha (ua ke nrog screwing), hauv kev txhawb nqa shock absorber (ua ke nrog riveting thiab vuam).

Kev sib dhos

Tom qab molding, kev sib dhos yuav siv sij hawm qhov chaw los ntawm robotic vuam ntawm cov khoom.

Kev ua tiav yog ua los ntawm kev sib tsoo thiab phosphating nrog 3 cations (Zn, Ni, Mn), uas txhawb nqa cov adhesion ntawm cataphoresis txheej los ntawm dipping.

Painting yog nqa tawm ib yam li rau steel lub cev. Twb tau nyob rau theem no, thawj qhov kev laus yuav tshwm sim, uas tom qab ntawd ua tiav los ntawm kev kho cua sov ntxiv ntawm 210 ° C rau 30 feeb.